Products

Custom high viscosity HydroxyPropyl Methyl Cellulose HPMC for mortar

Product description

Ordinary mortar belongs to cement mortar, strong economic requirements, but it is still relatively high for construction operability and mechanical spraying performance requirements, so higher requirements for sand grading and additives. In addition, mechanical construction will gradually become an important development direction of ready-mixed mortar. The use of suitable cellulose ether makes the mechanical construction possible.

Hydroxypropyl methyl cellulose(HPMC) is a non-ionic cellulose used in building materials, which can be dissolved in hot or cold water to form a transparent solution with a specific viscosity. it can improve construction performance, water retention performance, bond strength and sagging resistance.

Application

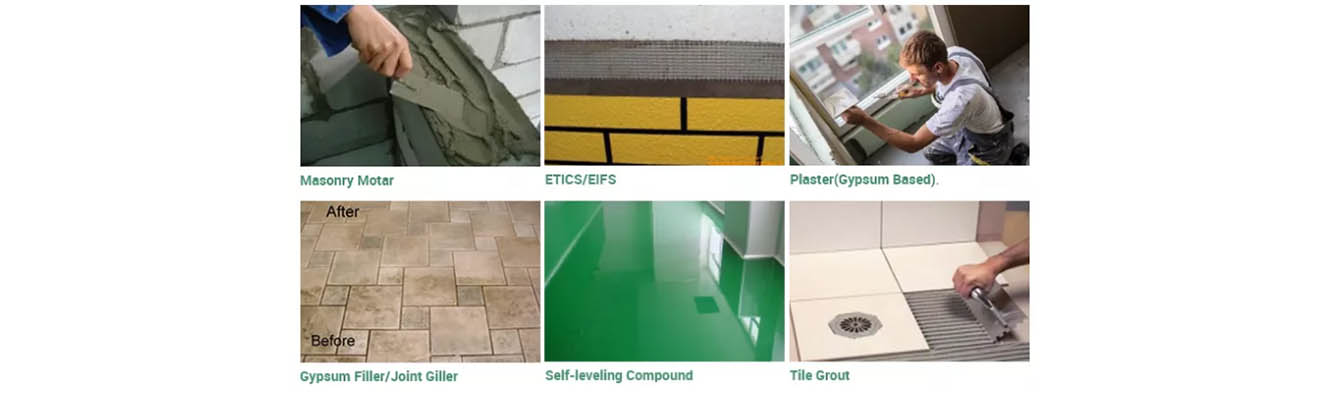

Normally HPMC is widely used in dry-mixed mortar industry, ceramic tile binder, External wall insulation system, self-leveling mortar, plasterer, putty, paint and so on.

Application range

● External wall insulation system

● Ceramic tile binder

● Joint filler

● Self-leveling mortar

● Plasterer/Putty

Product feature

● Maintain fluidity, improve water retention and reduce water absorption of mortar.

● Improve the anti-hanging property,make the slurry firmly adhere to the surface and not hang.

● Improve working performance, the lubricity of HPMC significantly improves the working performance of mortar, makes it easy to comb and coat, improves the working efficiency.

Advantages

● Good water retention.

● Good construction performance

● Good spraying and pumping performance

● Optimize the wetting ability of the base surface

● Cement hydration is more complete to achieve better bond strength and structure

● Long adjustable time

● Resistance to shrinkage

Product parameters

| Product Name | HPMC (Hydroxypropyl methyl cellulose) |

| Brand Name | Dongyuan |

| Particle size | 95% pass through 80 mesh |

| Viscosity(Brookfield RVT2%,20℃)cps | 50000 - 200000 |

| Methoxyl content % | 19-30 |

| Hydroxypropyl Content % | 4-12 |

| Place of Origin | Jinan, China |

| Application | Masonry mortar, plaster mortar, ground mortar, Thermal insulation mortar, waterproof mortar, anti-crack mortar, bonding mortar, base coat, repair mortar, interior and exterior wall putty, self-leveling, joint mixture, interface agent, tile glue, grouting material |

| Grade Standard | construction grade |

| Appearance | white or off white powder |

| Subject to the order requirement or contract |

|

Packaging & delivery

Net weight 25KG per valve bag

Net weight 0.6 Metric Tons per pallet

Pallet size(L*W*H): 1.1m*1.1m*1.1m

One 20'FCL=12MT with pallets or 14MT without pallets

Pallets are wrapped for stability and weather resistance

Port: Qingdao, China

Delivery time: ≦ 14 tons 5-7 working days after the payment

15 - 100 tons 10-20 working days after the payments

After- sale service

Our technician will be online 24 hours to service for the customers, any problem of the product you can contact us directly.

Payment terms & Express shipiing for sample:

Our factory & sales team

FAQ

1. Are you trading company or manufacturer?

Manufacturer, welcome to visit our factory.

2. How long is your delivery time?

Usually it is 3-7 working days, depends on the order quantity.

3. How can I get the price of a product?

Please provide the exact or approximate quantity, packing details, destination port or special requirements, then we could give you the price accordingly.

Why choose us?

At Dongyuan, we provide the following service to customers:

Study the properties of competitor’s product.

Help client to find matching grade quickly and precisely.

Formulation Service to improve performance and control cost, according to each client’s specific weather condition, special sand and cement properties, and unique working habit.

At Dongyuan, we have both Chemical Lab and Application Lab to ensure each order's best satisfaction:

Chemical labs is to allow us to evaluate properties as viscosity, humidity, ash level, pH, content of methyl and hydroxypropyl groups, substitution degree etc.

Application lab is to allow us to measure open time, water retention, adhesion strength, slip and sag resistance, setting time, workability etc.

Multi-lingual customer services:

We offer our services in English, Spanish, Chinese, Russian and French.

We have samples and counter samples of each lot to verify the performance of our products.

We take care of the logistic process until the destination port if the customer requires it.